Bringing Tomorrow’s Innovations to You Today

For the most innovative and highest-quality dental instruments choose Strauss Diamond, where innovation, quality, and education are our priorities. Our dental instruments are in use

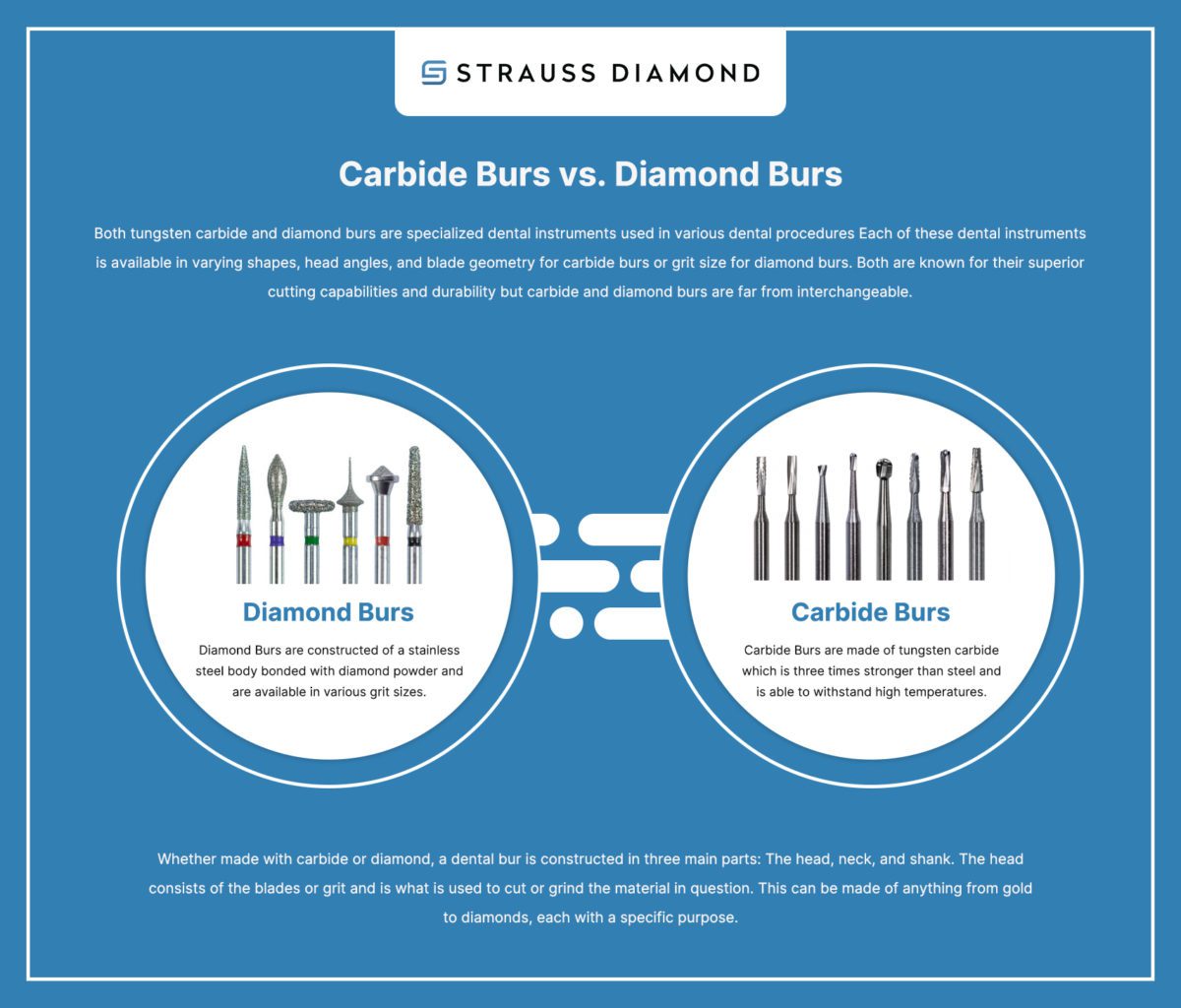

Both tungsten carbide and diamond burs are specialized dental instruments used in various dental procedures Each of these dental instruments is available in varying shapes, head angles, and blade geometry for carbide burs or grit size for diamond burs. Both are known for their superior cutting capabilities and durability but carbide and diamond burs are far from interchangeable.

Whether made with carbide or diamond, a dental bur is constructed in three main parts: The head, neck, and shank. The head consists of the blades or grit and is what is used to cut or grind the material in question. This can be made of anything from gold to diamonds, each with a specific purpose.

Diamond burs are constructed of a stainless steel body bonded with diamond powder and are available in various grit sizes. The side of the head and grit size decide what type of procedures the bur can be used in. Diamond burs are able to grind away hard tissues (such as enamel) and bone. Due to them being made from one of the hardest materials on earth they are ideal for cutting through harder materials that other burs struggle with such as Zirconia and lithium disilicate (please visit our Magic Touch line when working with these types of materials). Dental diamond burs are often used to cut through Zirconia or grind porcelain when shaping and placing crowns or veneers. They may also be used to grind down tooth structures in order to get proper fits for crowns or veneers.

One of the drawbacks of diamond burs is that they are not ideal for shaping materials such as metals as they are prone to dulling themselves in the process as well as overheating.

Tungsten carbide dental burs or more commonly known as just carbide burs are made of tungsten carbide which is three times stronger than steel and is able to withstand high temperatures. This allows carbide dental burs to be used much longer than other burs without losing their edge. These characteristics make them perfect for excavating cavities, shaping bone, removing impacted teeth, and many other procedures. Due to carbide burs using blades they are able to reduce vibrations (“chatter”) and in turn discomfort for patients.

Another advantage of carbide burs is their ability to cut through metal. Our specially designed Barracuda metal-cutting burs allow dentists to tackle even the toughest metal-cutting challenges like butter and save time with their multi-functional performance.

Diamond burs are also available in two separate options: single-use and multi-use. The single-use diamond bur allows the user to have a sterile and sharp bur for each new patient. Multi-use however is a more durable bur that offers a more economical option as the user is able to sterilize these burs. Another benefit is these burs are made for longevity making you able to get through an entire procedure with just one bur where with single-use burs you may have to use more than one to finish a task.

Overall carbide and diamond burs are functionally different. When using a carbide bur the bur is using small blades to slice away small pieces of the tooth while with diamond burs you are grinding the tooth down and leaving it with a rough surface that requires polishing later on with a separate tool. Each has its own benefits and weaknesses which makes both of them an important part of a dental professional’s arsenal.

For the most innovative and highest-quality dental instruments choose Strauss Diamond, where innovation, quality, and education are our priorities. Our dental instruments are in use

When running a dental practice it can be challenging to make your patients feel comfortable. After all, the fear of going to the dentist is

© 2021 StraussDiamond Return Policy Privacy Accessibility